DIAPHRAGM VALVES

ISIS High Purity currently work with a number of the world’s leading diaphragm valve manufacturers. We can supply most valves and spares to meet existing site specifications or alternatively we can offer a competitive solution. Please contact us today

2 WAY VALVES

The maintenance-free SISTO-C diaphragm valves made of forged stainless steel meet the stringent requirements applying in terms of sterility and purity. All ASME BPE valve models are built without dead volume and can be cleaned or sterilised without leaving any residues (SIP/CIP-compliant design), have a position indicator and are available with butt weld ends or clamps; straight-way, Y or T pattern, or as a multi-port valve; shut-off and sealing to atmosphere by completely enclosed diaphragm, making it the perfect valve for hygienic and sterile applications typically in the pharmaceutical, biotechnology and food & beverage industries.

NOMINAL PRESSURE

PN16

NOMINAL SIZE

DN 6-200

MAX. PERMISSIBLE PRESSURE

16 bar

MIN. PERMISSIBLE TEMPERATURE

-20°C

MAX. PERMISSIBLE TEMPERATURE

+160°C

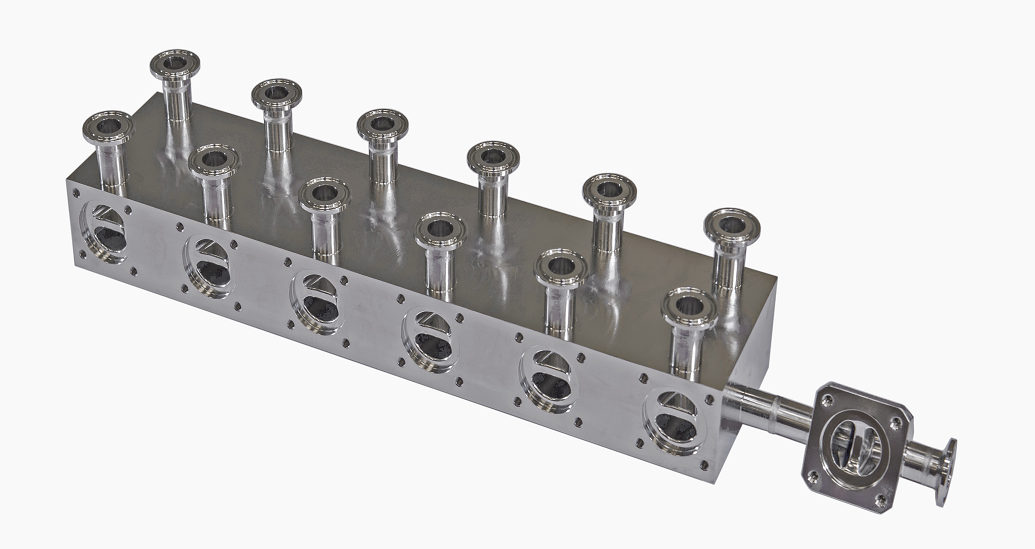

MULTI-PORT VALVES

Multi-port valves are often installed when complex solutions in process engineering systems are required. Compared with welded designs, these valves require minimal space and are optimised to prevent dead volumes. The block-bodied multiport valves are designed to meet your specific application requirements. Design allowing the installation of an enclosed diaphragm. Customised valve manufacturing. Optimised design for CIP/SIP routines. Compact, space-saving design. Minimised dead volume

SIZE

DN6 to DN150

TANK VALVES

SISTO-C tank bottom valves are typically welded onto the tank bottom at its lowest point. SISTO offers various design options for welding the valve into the tank.For welding onto tank bottom / -wall

● Customised valve manufacturing

● Variants:

– As Y-pattern body design

– With flush connection

– For welding onto tank wall

– As multiport-valve

● Allows complete draining

SIZE

DN 6 to DN 150

Y & T VALVES

SISTO-CY and SISTO-CT valves are manufactured from solid bar stainless steel material as standard. For larger nominal main pipe diameters, more cost-efficient variants with welded lateral pipe are available. SISTO-CY and SISTO-CT valves can be perfectly combined to create customised valve ring configurations. This allows modules to be configured which have no dead volumes and can be fully drained.

DIAPHRAGM VALVE 601 | 602 | 612 | 673

The GEMÜ 601, 612 and 673 manually operated aseptic diaphragm valves have a temperature resistant plastic handwheel, GEMÜ 602 has a stainless steel

handwheel. Bonnet and internals are made all of stainless steel.

An integral optical position indicator and a seal adjuster to increase service

life of the diaphragm are included as standard.

DIAPHRAGM VALVE 653 | 654

The GEMÜ 653 / 654 manually operated 2/2-way metal diaphragm valve

has a stainless steel bonnet and is available in two versions - GEMÜ 653

has a handwheel in high temperature and chemically resistant plastic,

GEMÜ 654 a stainless steel handwheel. The handwheel is non-rising

(except diaphragm size 8) and has a standard optical position indicator.

The valve is available with two bonnet versions: Design D has concealed

bolt mounting in the bonnet and is only suitable for 2/2-way bodies. Design

T is suitable for T valve, Multi-port valve, Tank bottom valve and 2/2-way

valve bodies.